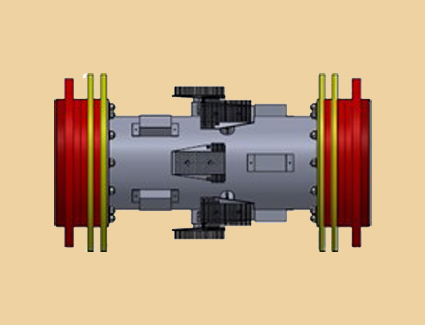

Bidirectional Pigs are used for a wide range of applications, from flood, clean and gauging operations to dewatering, as well as operational maintenance.

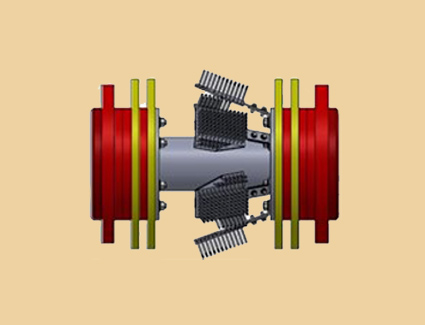

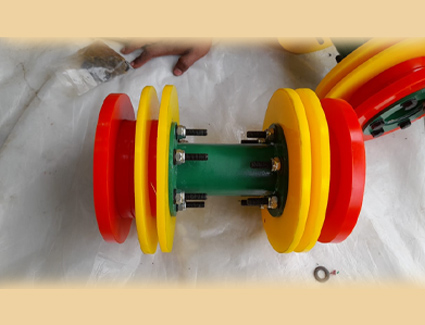

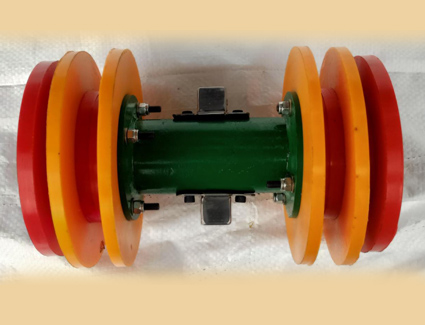

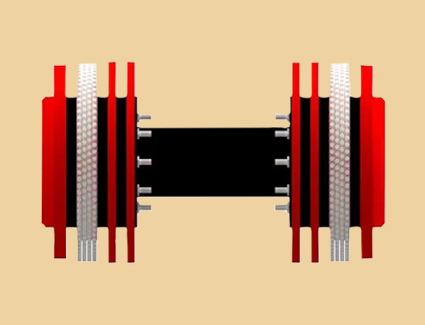

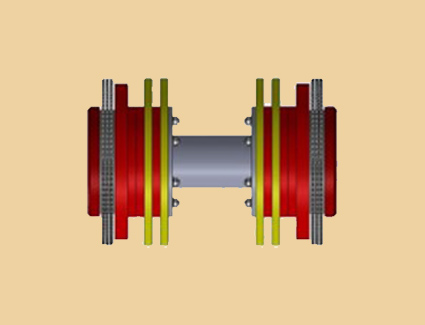

ARR pig configurations can be modified to run dual-diameter and multi-diameter pipelines as well as through features such as Wyes, Unbarred Tees, and Check Valves. Typically built with four sealing discs and two guiding discs, this can be enhanced to provide greater sealing, increased wear life, or even hold backpressure. ARR has a reputation for reliability and expertise in pig design for difficult pipelines.

Standard Features

- Carbon Steel or Stainless Steel (High Tensile Bolts c/w Locking Nuts)

- Pigging Discs – High-Grade Polyurethane Elastomer (4 x Sealing Disc and 2 x Guiding Disc minimum)

- Polyurethane Bumper Noses c/w Bypass Slots

- Bore Passing Up to 10% bore restrictions (greater with changes in disc configuration)

- Minimum Bend Radius 1.5D minimum

Optional Features

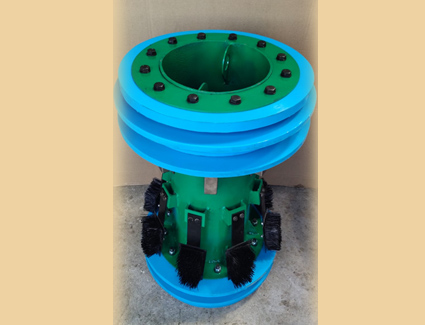

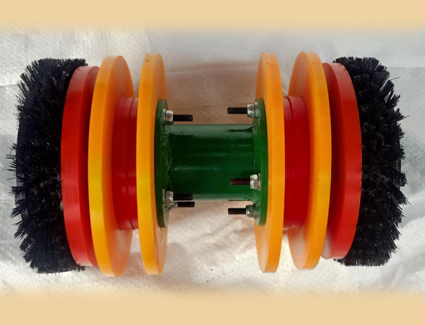

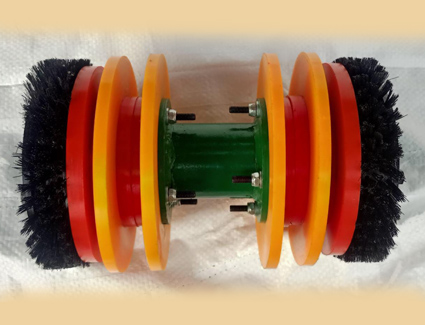

- Cleaning Brushes (Carbon Steel, Stainless Steel, or Nylon)

- Slotted or Grooved Guide Discs (for diameter changes or wax scraping)

- Dewaxing / Descaling Pads (with descaling studs)

- Gauging Plates

- Mounting for Pig Tracking Device

- Long Run Support / Guide Discs

- High Seal / High Friction layout

- Jetting / Bypass Nozzles for debris flushing and blockage prevention

- Magnet Packs for scale collection or detection

Bi-Directional Pig

Bi-Di Brush Pig

Bi-Di Magnetic Pig

Gauge Pig

Bi-Di Pig with Circular Wire Brush

Bi-Di Pig with Nylon Brush

Bi-Di Pig with Spring Loaded Brush

Bi-Di Magnetic Brush Pig

Bi-Di Pig with Single Arm Brush