Poly or Foam Pigs are used for a wide range of applications, such as flooding, dewatering, and drying, as well as cleaning, gauging, and batching operations. Foam pigs can also be used for proving pipeline suitability for pigging with less flexible pig types such as metal-bodied pigs.

The flexible nature of Foam pigs allows safe running in lines with wax or scale build-up (especially if deposit volumes are unknown). Foam pigs can be provided with varied aggression, from simple swabbing or inspecting pigs (for line proving) to the heavy density wire brush or Silicon carbide pigs.

ARR retains moulds for a full range of sizes, from 2" to 56" and these are custom-made to order.

Standard Features

- Standard Soft or low density for short runs

- Medium or Heavy Density for long runs

- Supplied as Bare / Coated Ends / Criss-Cross Poly Coated / Fully Coated

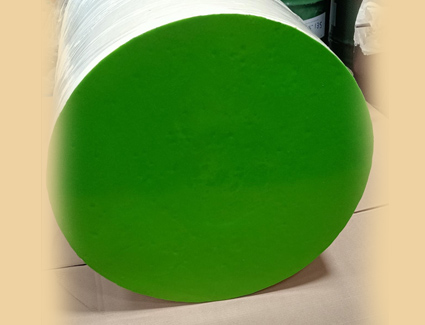

- High-Grade Polyurethane Elastomer coating

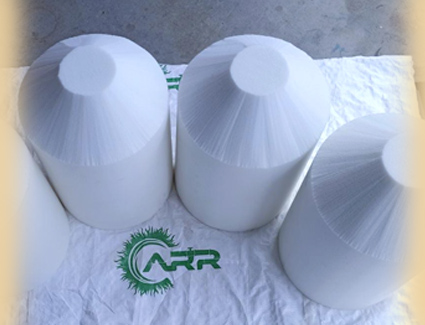

- Conical Nose and Concave Rear

- Bore Passing Up to 25% bore restrictions

- Minimum Bend Radius 1.5D minimum

Optional Features

- Cleaning Brushes (carbon steel, stainless steel, or nylon bristle)

- Bare, Criss Cross Coated, or Fully Coated

- Gauging Plate

- Tracking transmitter housing

- Pluggable Bypass Ports

- Signal Magnets

- Pulling / Lifting Loops

- Extended Body (Long Run / Wye)

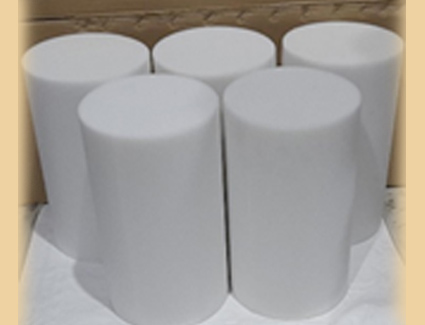

LD Bare Foam Pig

MD & HD Bare Foam Pig

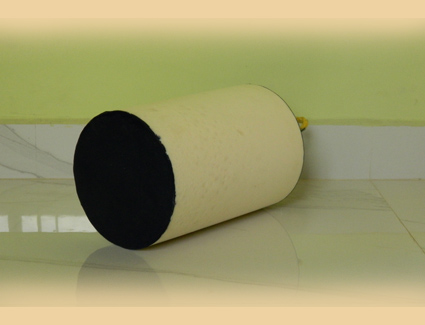

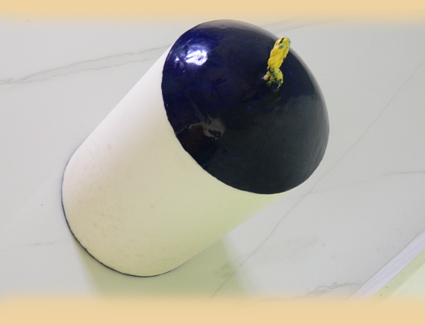

Bottom Coated Foam Pig

Top & Bottom Coated Foam Pig

Fully Coated Foam Pig

Criss Cross Foam Pig

Foam Pig with Wire Brush

Single Spiral Foam Pig

Foam Pig with Silicon Carbide Stripe

Foam Pig with Nylon Brush

Disc Foam Pig

Ball / Spherical Foam Pig

Foam Fenders